Understanding GGD Low Voltage Switchgear

The GGD Low Voltage Switchgear series is a type of fixed-type cabinet switchgear designed primarily for AC 50Hz power systems with a rated operational voltage of 380V. It is intended for power distribution, motor control, and lighting systems.

With models including GGD1, GGD2, and GGD3, the system covers a wide range of operational requirements, featuring rated currents from 400A to 3150A and short-circuit breaking currents up to 50kA.

Developed based on IEC 439 and GB7251 low-voltage switchgear standards, GGD offers enhanced safety, flexibility, and maintainability.

Application Scenarios for GGD Switchgear

- Industrial Plants: Primary and secondary distribution networks, motor control centers.

- Commercial Buildings: Shopping malls, office towers, and airports.

- Infrastructure Projects: Power stations, transportation hubs, and water treatment plants.

- Healthcare Facilities: Stable and protected electrical distribution for hospitals and research centers.

According to Wikipedia, low voltage switchgear is vital for the secure distribution of electricity in diverse environments.

Market Trends and Industry Insights

Global trends show a rising demand for reliable low-voltage power distribution systems, driven by rapid industrialization and modernization of infrastructures. According to reports from IEEE and IEEMA, low-voltage switchgear markets are expanding significantly, especially in regions adopting smart grid technologies and sustainable energy systems.

Key manufacturers like ABB, Schneider Electric, and Siemens have consistently updated their low-voltage switchgear lines, emphasizing safety, flexibility, and compatibility with digital monitoring systems.

Technical Specifications of GGD Switchgear

| Model | Rated Voltage (V) | Rated Current (A) | Short-Circuit Breaking Current (KA) | Short-Time Withstand Current (1s) (KA) | Peak Withstand Power (KA) |

|---|---|---|---|---|---|

| GGD1 | 380 | 1000 / 600 / 400 | 15 | 15 | 30 |

| GGD2 | 380 | 1500 / 1000 / 600 | 30 | 30 | 63 |

| GGD3 | 380 | 3150 / 2500 / 2000 | 50 | 50 | 105 |

The series offers a comprehensive range to address light, medium, and heavy-duty power distribution needs.

Differentiating GGD from Other Low Voltage Systems

- Fixed-Type Structure: Unlike withdrawable systems like GCK or GCS, GGD uses a fixed-type cabinet, offering high stability and lower cost.

- Enhanced Mechanical Strength: Rugged design suitable for harsh industrial environments.

- Simplified Maintenance: Modular panel components allow for easier inspection and parts replacement.

- Cost-Effective: GGD systems are generally more affordable and easier to deploy compared to complex modular systems.

While GCS and GCK offer greater flexibility, GGD is optimal for applications where cost-efficiency and mechanical robustness are the priority.

Selection Tips and Buying Advice

When choosing GGD switchgear, consider the following factors:

- Rated Current and Short-Circuit Capacity: Ensure the system can handle peak and fault currents of your operation.

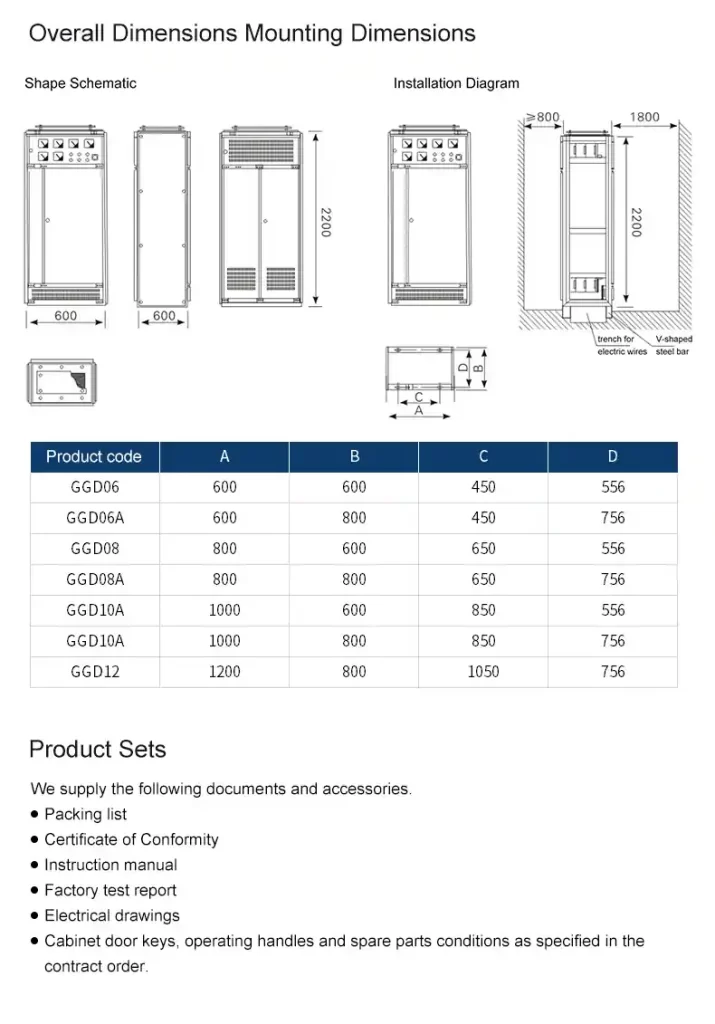

- Cabinet Size and Layout: Match cabinet dimensions and access needs based on installation space.

- Protection Requirements: Check compliance with IP standards and grounding specifications.

- System Integration Needs: Evaluate compatibility with monitoring devices or automated control systems if needed.

Always consult technical experts or certified suppliers to align switchgear features with project-specific demands.

Frequently Asked Questions (FAQ)

A1: GGD switchgear is ideal for environments requiring robust, fixed-type distribution solutions such as industrial plants, commercial facilities, and infrastructure projects.

A2: Regular inspections every 6 to 12 months are recommended to ensure optimal performance and early detection of potential issues.

A3: While GGD systems are less modular than withdrawable types, additional panels can often be integrated if planned appropriately during the initial design.

This detailed review of GGD Low Voltage Switchgear demonstrates its reliability, structural strength, and cost-effectiveness, making it a trusted solution for modern electrical power distribution.